How to Ensure Your Safety Equipment Meets Compliance Standards in the USA

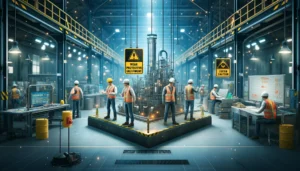

How to Ensure Your Safety Equipment Meets Compliance Standards in the USA Ensuring workplace safety is a legal and moral responsibility for businesses in the United States. Using the right safety equipment is critical to protecting employees and avoiding costly penalties, from construction sites to manufacturing plants. However, simply having safety gear isn’t enough—it must meet federal and industry-specific compliance standards. This guide’ll explore how businesses can ensure their safety equipment aligns with OSHA (Occupational Safety and Health Administration) regulations, ANSI (American National Standards Institute) certifications, and other relevant standards. Plus, we’ll highlight why sourcing your equipment from the best safety equipment suppliers in Texas can make compliance easier and more cost-effective. Understanding Safety Compliance Standards in the USA Before purchasing or using safety equipment, businesses must understand the primary organizations setting compliance standards: OSHA Regulations The Occupational Safety and Health Administration (OSHA) sets national standards for workplace safety. OSHA’s regulations for personal protective equipment (PPE) are found in 29 CFR 1910 Subpart I and include requirements for: Eye and face protection Hand and foot protection Respiratory protection Head protection (hard hats) Hearing protection Protective clothing for hazardous environments Non-compliance can result in hefty fines and increased liability risks for businesses. ANSI and ASTM Standards The American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM) establish safety performance criteria for various types of PPE. Compliance with these standards ensures safety gear meets rigorous testing for durability, impact resistance, and effectiveness. Key ANSI/ASTM safety categories include: ANSI Z87.1 for eye protection ANSI Z89.1 for hard hats ASTM F2413 for safety footwear ANSI Z41 for work gloves NFPA and NIOSH Guidelines The National Fire Protection Association (NFPA) sets safety standards for fire-resistant clothing and other fire-related safety gear. The National Institute for Occupational Safety and Health (NIOSH) provides certification for respiratory protection equipment, such as N95 masks and self-contained breathing apparatus (SCBA) systems. Steps to Ensure Your Safety Equipment is Compliant Source Equipment from Reputable Suppliers The first step to compliance is purchasing safety gear from trusted suppliers. The best safety equipment suppliers in Texas provide OSHA- and ANSI-certified PPE to ensure legal and workplace safety compliance. Look for vendors that: Offer products from well-known, certified brands. Provide documentation proving compliance with U.S. safety standards. Have knowledgeable staff who can guide you on proper equipment selection 2. Conduct a Workplace Hazard Assessment OSHA mandates that employers perform a hazard assessment to determine what type of PPE is necessary for their workforce. This involves: Identifying potential hazards (e.g., chemical exposure, falling objects, noise pollution). Determining the required PPE based on OSHA guidelines. Documenting the assessment and keeping records for compliance verification. 3. Verify Equipment Certifications and Labels Before purchasing, always check for compliance markings such as: ANSI/ASTM/NFPA labels on PPE. NIOSH certification on respiratory protection. Manufacturer test reports and compliance documents to verify authenticity. Counterfeit safety gear is a growing concern, so always buy from reputable distributors to avoid non-compliant or low-quality products. 4. Train Employees on Proper PPE Usage Even the most advanced safety gear is ineffective if employees don’t use it correctly. OSHA requires businesses to provide training on: How to wear and adjust PPE for maximum protection. When and where PPE is required. How to inspect and maintain safety equipment. Regular training sessions reduce workplace injuries and ensure employees adhere to compliance standards. 5. Perform Regular Inspections and Maintenance Over time, safety equipment can degrade, affecting its performance. Implement a routine inspection and maintenance program by: Checking PPE for wear and tear (e.g., cracks in hard hats, torn gloves, scratched safety goggles). Replacing expired or damaged safety gear immediately. Keeping maintenance logs to demonstrate compliance with OSHA audits. 6. Stay Updated on Changing Regulations Safety compliance laws evolve, and staying informed is crucial to avoid non-compliance penalties. Subscribe to OSHA updates, join industry safety forums, and consult with safety equipment experts to keep up with new regulations Why Choosing the Best Safety Equipment Suppliers in Texas Matters Purchasing from reputable Texas-based safety equipment suppliers ensures you get high-quality, compliant gear tailored to local industry needs. Top suppliers offer: Guaranteed compliance with OSHA and ANSI standards. Bulk purchasing options for businesses with large workforces. On-site consultations to recommend the right PPE for your operations. Fast delivery across Texas to ensure businesses stay stocked with safety gear. Ensuring that your safety equipment meets U.S. compliance standards is essential for protecting workers, avoiding fines, and maintaining a productive workplace. By sourcing PPE from the best safety equipment suppliers in Texas, conducting regular hazard assessments, and staying informed on regulatory updates, businesses can confidently meet OSHA and ANSI standards. Investing in certified, high-quality safety equipment not only enhances workplace safety but also demonstrates a company’s commitment to employee well-being and legal compliance. Need help choosing the right PPE? Reach out to a trusted Texas safety equipment supplier today!