Menu

Menu

Table Of Contents

How to Choose the Right Drum Lifter: Manual Guide 2025

Selecting the right drum lifter for your industrial needs can significantly enhance safety and efficiency in your material handling operations. A drum lifter is essential for businesses involved in the transportation and handling of large, heavy drums, offering a secure and reliable means of lifting, moving, and setting down drums without the need for additional manpower. As a distributor of high-quality drum lifters, Lint Land aims to provide you with an in-depth guide on choosing and using the best lifter for your operations in 2025.

Why Drum Lifters are Essential for Industrial Operations

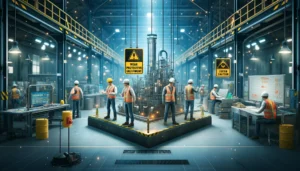

Drum lifters simplify handling heavy, bulky drums, reducing the risk of injury or product damage. They are particularly useful in industries that manage hazardous or bulk liquids, chemicals, and materials stored in 30- or 55-gallon drums. A suitable drum lifter allows operators to handle these loads efficiently and safely, making it a valuable tool in warehouse, manufacturing, and logistics environments.

Key Considerations When Choosing a Drum Lifter

Here are the main factors to consider when selecting a drum lifter:

Steps for Using a Drum Lifter Safely

Operating a drum lifter correctly ensures a safer work environment and prolongs the life of your equipment. Below is a step-by-step guide based on standard usage practices:

Step 1: Inspect the Lifter Before Use

Before each use, visually inspect the drum lifter for any signs of wear or damage. Confirm that the jaws, shackle, and lifting arms are intact and in good working order. Make sure all bolts and pins are securely fastened.

Step 2: Secure the Drum Lifter to the Lifting Device

Attach the lifter’s shackle to the safety hook of your hoist or lifting device. Ensure that the shackle pin is properly fastened for secure attachment.

Step 3: Position the Lifter Over the Drum

Lower the lifter over the drum, ensuring the jaws are fully open. Use the handle to maneuver the lifter into position, making sure the jaws align with the top rim of the drum.

Step 4: Clamp the Drum Securely

Close the jaws to grip the drum’s rim securely. Lift the drum just a few inches to test the grip, ensuring the lifter is firmly holding the drum. Allow the lifter to hold the drum momentarily while you check for any signs of slippage or instability.

Step 5: Transport the Drum

Slowly lift the drum to the required height (about 5-6 inches for overhead hoists). When moving, avoid sudden movements that could cause the drum to swing. Forklift operators should drive slowly, especially during turns and when braking.

Step 6: Lower the Drum Safely

Once you reach the destination, lower the drum carefully. Ensure there’s slack in the lifting chain before releasing the jaws. Avoid leaving suspended drums unattended.

Maintenance Tips for Prolonged Equipment Life

Proper maintenance is essential for reliable and safe operation. Lint Land recommends making a written record of the lifter’s condition before its first use. Here’s what to inspect regularly:

Important Safety Guidelines

Following essential safety practices can prevent accidents and damage to your drum lifter. Here are some key points to remember:

Understanding Lint Land’s Warranty Policy

Lint Land stands behind its products, offering a comprehensive warranty on its drum lifters. Here are some key points about the warranty:

Final Thoughts

Choosing the right drum lifter involves considering the lifter’s specifications, safety features, durability, and compatibility with your operational needs. Regular maintenance and adherence to operational guidelines ensure the lifter remains a safe, efficient tool in your daily processes. By following this manual and investing in a quality lifter from Lint Land, you can maximize productivity and maintain a safe work environment