Menu

Menu

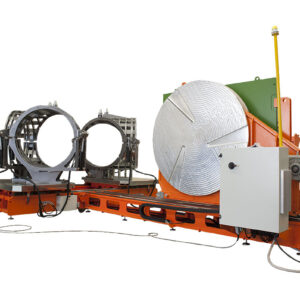

The OMEGA 400 – 315 and OMEGA 630 – 315 are specialized saddle fusion machines designed for workshop use, ideal for manufacturing custom parts such as reduced tees and crosses. These machines are tailored for water pipeline applications, particularly in drainage and sewerage systems. With precision engineering and user-friendly features, they ensure efficient and reliable saddle fusion processes.

The OMEGA 400 – 315 and OMEGA 630 – 315 saddle fusion machines combine robust design, advanced functionality, and ease of use to meet the demands of workshop applications. Their precision and adaptability make them indispensable tools for creating custom parts in water pipeline projects.