Menu

Menu

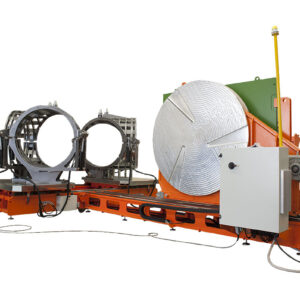

Technical features:

| Materials | HDPE/PP/PB/PVDF |

| Working range | Ø 75 ÷ 250 mm; 2″ IPS ÷ 8″ DIPS |

| Power supply | 110 V or 230 s-phase 50/60 Hz |

| Total absorbed power | 4400 W (110 V) 4200 W (230 v) |

| Working temperature | 180° ÷ 260° C (356° ÷ 500° F) |

| Outside temperature range | -10° ÷ 40° C (14° ÷ 104° F) |

| Weight | 227 Kg (500 lb) |

| Dimension | 1100 x 1340 x 1300 mm 43.3″ x 52.7″ x 51.1″ |

The DELTA 250 TRAILER MANUAL is a self-aligning hydraulic butt fusion machine designed for welding underpressure pipes used in water, gas, and other fluid systems up to Ø 250 mm (8″ DIPS). Compliant with international standards such as ISO 21307 HIGH PRESSURE and ASTM F2620, this machine offers precision and efficiency for various pipeline welding applications.

The DELTA 250 TRAILER MANUAL is a robust and innovative solution for professionals in pipeline installation and maintenance. Its portability, advanced features, and compliance with international standards make it an excellent choice for reliable and efficient butt fusion welding.