Menu

Menu

Technical features:

| Materials | HDPE/PP/PP-R |

| Working range | Ø 20 ÷ 315 mm |

| Power supply | 110 V single phase 50/60 Hz 230 V single phase 50/60 Hz |

| Totally Absorbed Power | 2600W |

| Max output current | 100 A |

| 60% Duty Cycle Output | 23 A |

| Memory capacity | 500 reports |

| Degree of protection | IP 54 |

| Dimensions machine body | 263 x 240 x 300 mm |

| Dimensions transport case | 405 x 285 x 340 mm |

| Weight | 16 Kg |

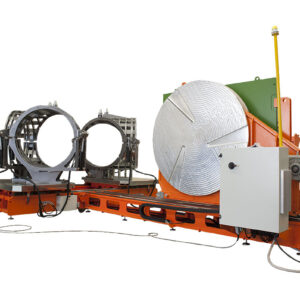

The ELEKTRA 315 is a universal and lightweight electrofusion machine designed for welding pipes and fittings used in the transport of gas, water, and fire sprinkler systems. It is compatible with HDPE, PP, and PP-R couplings in the range of 8 to 48 V. Built to comply with international standards, the ELEKTRA 315 offers high portability, efficiency, and advanced data management capabilities.

The ELEKTRA 315 is the ideal solution for professionals looking for a portable, reliable, and efficient welding machine. Its advanced features and compliance with international standards ensure consistent and high-quality results for various applications in gas, water, and fire sprinkler installations.