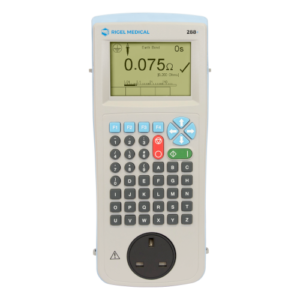

The HAL LED has been designed with a reduced power measurement range with greater resolution than the HAL 104, making it ideal for the testing of low power electronics such as LED lighting.

| Features | 101 | 103 | 104 | LED |

| Earth/Ground Bond | ||||

| AC Flash/Hipot | ||||

| DC Flash/Hipot | ||||

| DC Insulation Resistance | ||||

| ARC Detection | ||||

| Leakage | ||||

| Load Power | ||||

| Load Power (200mVA resolution) | ||||

| Power Factor | ||||

| Results Memory | ||||

| Automation Option | ||||

| Barcode scanner/printer Option |

Engineered for optimal productivity and efficiency in safety testing along LED and luminaire production lines, the HAL LED also boasts high-resolution power measurement capabilities, enhancing quality control measures. Compliant with UL 1598 and UL 8750 standards, the HAL LED ensures rigorous testing standards are met.

200mVA Resolution Power Measurement

As LED lighting gains popularity among environmentally conscious consumers, manufacturers strive to deliver more efficient lighting solutions to remain competitive. With a 200mVA resolution, the HAL LED enables manufacturers to accurately measure the output of each product, ensuring it meets acceptable power limits. This provides manufacturers with assurance that the correct components, such as LED drivers, were installed during production.

Ideal for medium to large-scale electrical manufacturers, including LED lighting manufacturers, importers, QA and product auditing departments, and producers of low-powered equipment.

Traceable Results

In response to increasing pressure from quality systems for traceable and accurate results, the HAL LED simplifies the process by automatically logging test results. Each tested product is stamped with date and time, along with an optional product identifier such as a serial or batch number. With a large memory capable of storing 6000 tested products, even the busiest production lines can maintain comprehensive records.

Flexible User Configurable Test Sequences

Equipped with the ability to store up to 50 test sequences in automatic mode, the HAL LED offers flexibility in testing procedures. Each test sequence can consist of up to 5 individual tests, providing a structured and repeatable approach to end-of-production-line testing. This ensures adherence to required test parameters and timings.

Designed with Safety in Mind

To comply with safe test area requirements outlined in EN 50191, the HAL LED incorporates various safety features. Isolated test outputs during Flash (HiPot) and Insulation resistance tests minimize the risk of electrical shock. The built-in guard switch automatically disconnects test voltages if opened, enhancing safety in case of accidental entry into the test area during hazardous tests. Additionally, a ‘plug and play’ style beacon port enables clear identification when high voltage testing is in progress.