Menu

Menu

Technical features:

| Materials | HDPE/PP |

| Working range | Ø 125 ÷ 355 mm Ø 4” ÷ 14” IPS Ø 4” ÷ 12” DIPS |

| On-board generator * | 719cc – 14 Kw |

| Fuel | Diesel |

| Fuel tank | 43 litres (11.3 gal) |

| Autonomy | 21 Hours |

| Max operating slope | 35% |

| Emission compliance | EPA US TIER 4 FINAL, EU STAGE V |

| Total weight | 1170 Kg (2579 lb) |

| Body machine sizes Max dimensions on site | 3007 x 1479 x 1690 mm 9.86 x 4.85 x 5.54 ft |

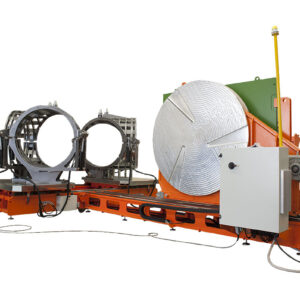

The REMEDY 355 is a high-productivity, independent welding machine designed for butt welding HDPE and PP pipes ranging from Ø 125 to 355 mm (4” to 14” IPS; 4” to 12” DIPS). Equipped with tracks and powered by a diesel on-board generator, it is built for versatility, accuracy, and reliability, meeting ISO 21307 High Pressure and ASTM F2620 fusion standards. This self-propelled machine is ideal for demanding environments and tough conditions.

The REMEDY 355 comes with a Manual Welding Control System. Its intuitive control panel allows for easy manual management of every phase of the welding cycle, ensuring precision and flexibility.

The REMEDY 355 delivers robust performance, ease of use, and exceptional reliability, making it a go-to solution for pipeline welding in challenging environments.