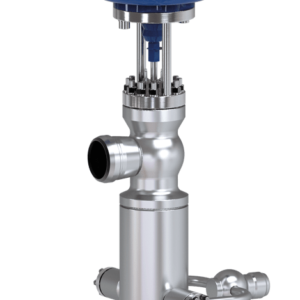

IMI CCI 100DLC DRAG® Valve: The Ultimate One-Valve Solution for Drum and Boiler Level Control

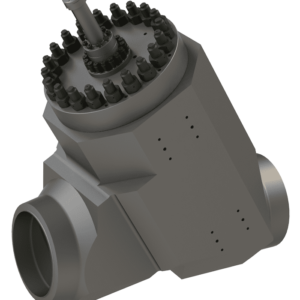

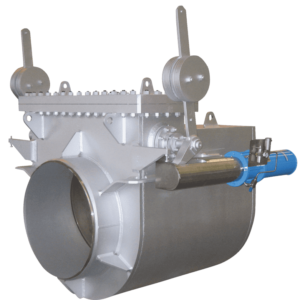

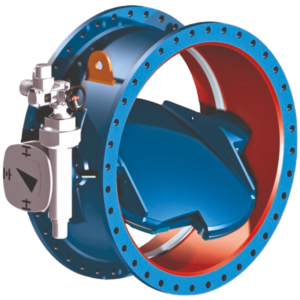

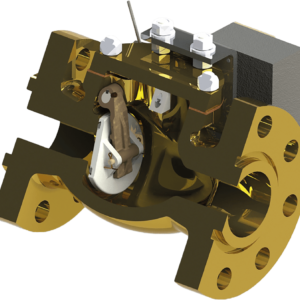

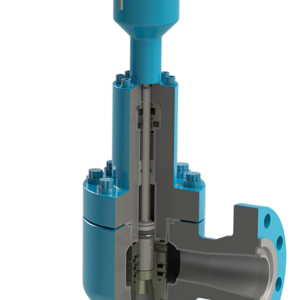

The IMI CCI 100DLC DRAG® valve offers a single-valve solution for drum and boiler level control, eliminating the need for traditional two-valve systems. This innovative valve combines high and low Cv requirements, providing exceptional performance across all flow conditions—from startup to normal operation. Powered by DRAG® high-rangeability trim, the valve ensures precise controllability and reliability in even the most demanding applications.

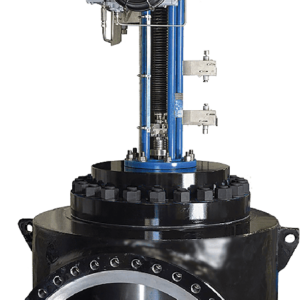

IMI CCI offers tailored solutions for high-temperature and other challenging environments, ensuring that the 100DLC DRAG® valve meets the specific demands of your operation.

The 100DLC DRAG® valve simplifies drum and boiler level control with its one-valve configuration, providing a cost-effective, space-saving, and efficient alternative to traditional two-valve systems. With its high-rangeability trim and advanced sealing technologies, the valve guarantees precise flow control and long-term reliability, making it the ideal choice for applications requiring flexibility, durability, and high performance.