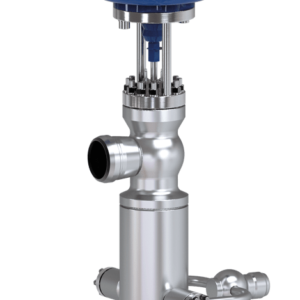

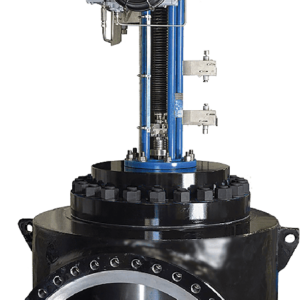

IMI CCI 100DPC Production Choke Valve: Durable Solutions for Severe Oil and Gas Applications

The 100DPC production choke valve is specifically engineered for the most demanding wellhead applications in the oil and gas industry. Positioned where well fluid is first extracted, this valve must handle extreme conditions, including multi-phase fluids, high pressures, and corrosive elements. The 100DPC is designed to provide precise pressure control for downstream processes while minimizing wear and ensuring long-term reliability.

The IMI CCI 100DPC production choke valve sets the standard for severe service wellhead applications. With its robust materials, innovative design features, and field-proven DRAG® technology, it delivers exceptional performance in the face of erosion, corrosion, and high-pressure conditions. Engineered to handle the toughest challenges, the 100DPC valve ensures reliability, efficiency, and reduced operating costs for oil and gas operators worldwide.